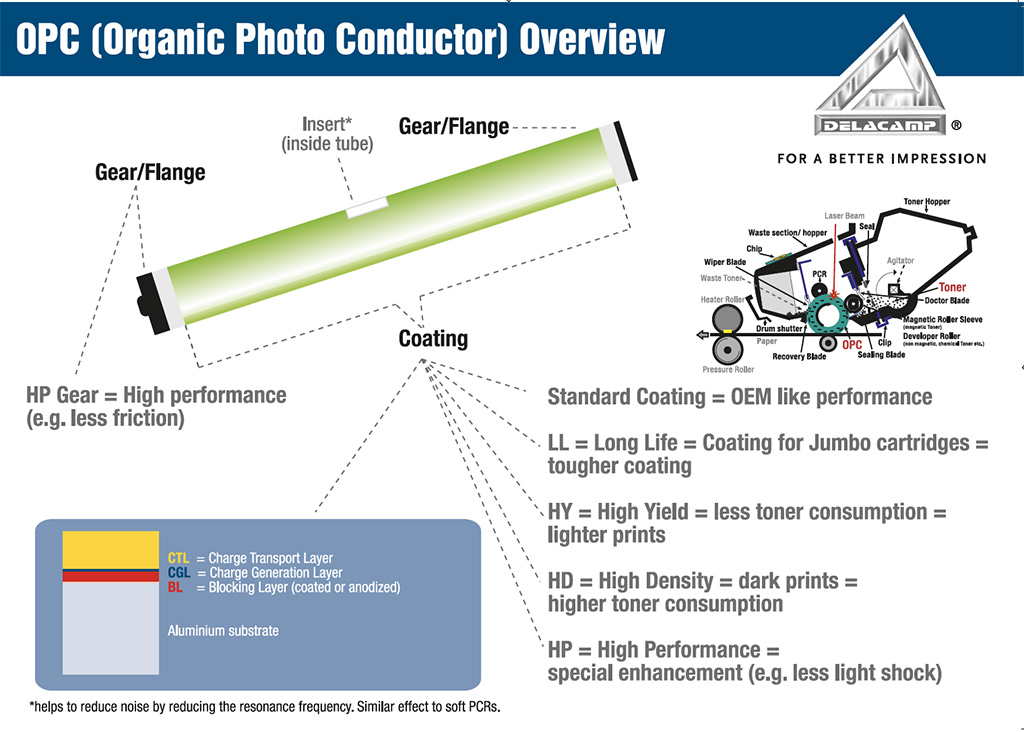

Information on OPC

1. Climatic conditions

Temperature // Storage Life (cumulative)

up to 25°C (77°F) // 2 years (advised temperature)

up to 35°C (95°F) // 4 months

up to 45°C (113°F) // 200 hrs

over 45°C (113°F) // Not allowed

Relative humidity: 25–85 % rh

Any condensation and exposition to chemical vapors must be avoided during storage, transportation, installation and operation.

2. Storage and Transportation Conditions

Stacking Limits:

In order to prevent mechanical damage caused by deformation of packaging the height of stack level of pallets is limited to: 2 pallets or 10 master boxes whichever is reached first.

The outside pallet feet must not reach more than 4 cm (1.5 inches) above the edge of the top layer of the carton boxes. Otherwise a protection plate (e.g. a wooden separator board) must be used before the upper pallet is stored on top of the lower pallet.

Stacking of pallets during transportation is not allowed.

3. Operating Conditions

The recommended operating conditions are 20 – 25 °C / 68-77°F and 40–60% rh.

The performance of OPC drums depends on climatic conditions. Under high temperature (> 30°C / 86°F) and high humidity (> 80% rh) dark decay may increase whereas at low temperature (< 15°C / 59°F) and low humidity (< 30% rh) sensitivity may decrease.

This change of the drum properties is not permanent but reversible. After storage under normal conditions (e.g. 20°C / 68°F and 50% rh) the drum recovers to its initial performance. Depending on the storage time under adverse temperature and humidity, recovery of the drum properties may take several days.

1. Impact damage

- Mechanical damage

Reason of damage: Mechanical defect during transport, service or handling.

Appearance: Dints or holes causing print defects. - Contamination of drum surface

Reason of damage: Contamination with fingerprints, adhesives (label printing), melted toner particles (toner quality) etc.

Appearance: Filming, discoloration. - Damage of drum surface by solvents, oil, fingerprints and skin protection grease

Reason of damage: Contamination of the photoconductive layer by lubrication grease, oil, cleaning solvents or skin protection grease during storage, handling and installation of the OPC drum. This type of materials as well as chemicals evaporating from components of the copier, printer or cartridge (e.g. PCRs, cleaning blades, etc.) will create cracks of the OPC layer during further storage.

Appearance: Irregular thin black lines on prints.

2. Wear

- Decrease of thickness of the photoconductive layer

Reason of damage: Abrasion of the photoconductive layer caused by the copier or printer design, supplies materials and OPC properties.

Appearance: Circumferential lines or scratches on the layer, which causes in extreme cases lines or background on prints.

3. Environmental conditions

- Change of electrical performance of OPC

Reason of damage: Chemical reaction indicated by:

– chemical vapors,

– extreme temperature and humidity conditions

– exposure to bright light

Appearance: Filming, discoloration of OPC layer. Poor or uneven print density. Blurred print image.

1. General

OPC surfaces cannot be compared to other painted surfaces. The OPC coating is not only a protective or decorative coating of the substrate. It is a semiconducting part and therefore very sensitive regarding contamination, chemical reactions and physical contact.

2. Effect of cleaning to performance

Scheduled OPC cleaning routines (e.g. during other service activities) do not significantly increase life or reliability of an OPC. Some drums might perform slightly better after cleaning but other drums are damaged during cleaning and must therefore be replaced immediately even if they still could have been used without cleaning. The average drum life will not increase by cleaning.

3.Why do drums have to be cleaned?

The need of cleaning OPC drums is generated only by use of poor quality toner, developer, paper or cleaning blade.

4. Cleaning procedure

- The surface of an OPC drum must never be touched with fingers. While handling, the drums should be held only by the flanges.

- Water, oil or organic solvents must never be applied to the OPC surface. There is a very high risk of contamination of the surface with residues and of chemical reactions with the OPC coating which extremely shortens the economic life-time of the drum.

- The drum must never be exposed to bright light and should be stored in the dark.

- Take extreme care not to scratch or dent the surface of OPC drums.

5. Recommendation

We strongly recommend not to clean OPC drums. Nevertheless, if cleaning of OPC drums is necessary for any reason, use dry dust free cotton pads. Avoid any hard pressure on the surface. Use a clean cotton pad to clean the entire drum surface. Turn the drum slowly in rotational direction while wiping the drum. Replace the cotton pad frequently.